Some plastics already have good wear resistance. After adding various wear-resistant additives, their wear resistance can be improved. These additives like polytetrafluoroethylene, molybdenum disulfide, graphite, silicone oil, glass fiber, carbon fiber and aromatic polyamide fiber additives made of plastic composite materials have self-lubricating (selflubricating), and can reduce the matching parts Pressure to improve the wear resistance of the material.

Let's take a look at the materials that can improve the wear resistance of the material.

1. Polytetrafluoroethylene (PTFE, Teflon)

PTFE has the lowest coefficient of friction among all anti-additives. The PTFE molecules that are ground out during the friction process will form a lubricating film on the surface of the part. PTFE has good lubricity and wear resistance under frictional shear. In high load applications, PTFE is the best wear resistance additive. These high loads include hydraulic piston ring seals and thrust washers. The most appropriate PTFE content is 15% PTFE for non-crystalline and 20% PTFE for crystalline plastics.

2. Molybdenum disulfide

Another common name for molybdenum disulfide is "Moly", a wear-resistant additive mainly used in nylon plastics. Molybdenum disulfide acts like a crystallization agent to increase the crystallinity of nylon and make nylon material produce a harder and more abrasive surface. Molybdenum disulfide has a high affinity for metals. Once adsorbed on the metal surface, the molecules of molybdenum disulfide will fill the metal surface with microscopic pores, and make the metal surface more slippery. This makes molybdenum disulfide an ideal wear-resistant additive for applications where nylon and metal rub against each other.

3. Graphite

The chemical structure of graphite is a unique lattice structure. This unique chemical structure allows graphite molecules to slide easily on each other with little friction. This abrasion resistance is especially important in environments with water. This characteristic makes graphite an ideal abrasion resistance additive for many applications placed in water, such as water paving shells, impellers and value seals.

4. Polysiloxane

Polysiloxane fluid is a migratory wear-resistant additive. When added to thermoplastics, the additive will slowly migrate to the surface of the part and form a continuous film. Polysiloxane has a wide range of viscosity, and the viscosity is measured in centistokes. The viscosity of polysiloxane is extremely low, and it moves to the surface of the part in a fluid state to provide wear resistance. If the viscosity of polysiloxane is too low, it will be more volatile and will quickly disappear from the part.

5. Glass fiber

Glass fiber is a kind of hard fiber with high scratch resistance, so it is often mistaken that adding glass fiber to plastic will destroy the wear resistance of the plastic. Glass fiber provides the function of strong mechanical bonding between polymers, so glass fiber can increase the integrity of the thermoplastic structure and improve wear resistance. The reinforcement provided by glass fiber can increase the creep resistance, thermal conductivity and thermal deformation of the plastic, which can significantly improve the resistance to load and abrasion speed of the plastic.

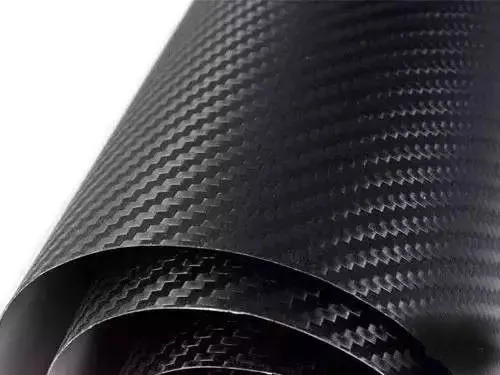

6. Carbon fiber

As with glass fiber, carbon fiber can greatly improve the structural integrity, abrasion resistance, load resistance and abrasion resistance. Unlike glass fiber, carbon fiber is a softer and less scratchy fiber. Carbon fiber will not scratch the friction surface of iron steel or steel with which it rubs. The addition of more than 10% of carbon fiber to thermoplastics will have the function of eliminating static electricity and thus overcome the static electricity problem caused by it.

7. Aromatic polyamide fiber

Aromatic polyamide fiber is also one of wear-resistant additives. Unlike glass fiber and carbon fiber, it is the softest and least scratch-free fiber. This feature is the main advantage of aramid fibers in wear-resistant applications, especially the fibers that are scratch-resistant on the surface of mating parts.