- Portada

- Sobre nosotros

- Producto

- Plancha de PTFE Expandido MORE

-

Cinta de PTFE Expandido

- Cinta Selladora de Juntas de PTFE Expandido

- Cinta de PTFE para Sellado de Roscas

- Cinta de PTFE para SWG

-

Productos de PTFE

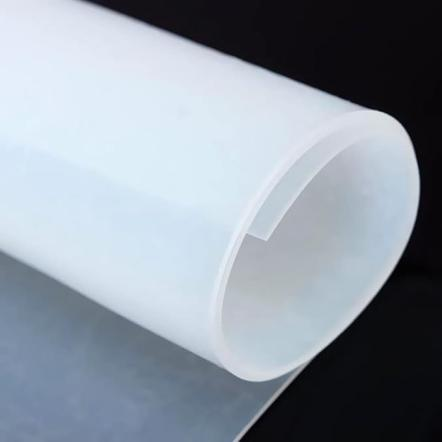

- Plancha de PTFE

- Barra de PTFE

- Tubo de PTFE

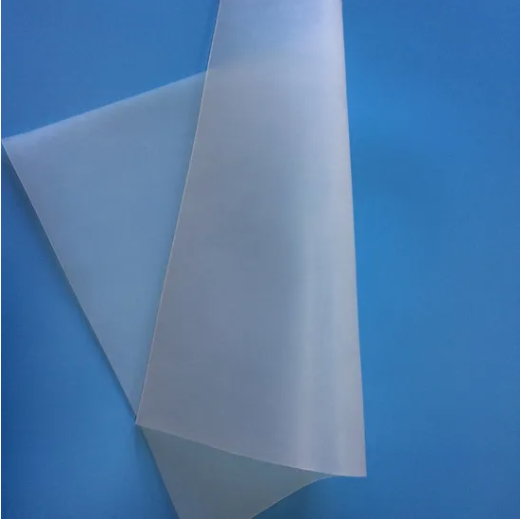

- Película de PTFE

- PTFE modificado

- Tela de Fibra de Vidrio Recubierta de PTFE

- Plastico de Ingenieria MORE

-

Materiales de Sellado

- Empaquetadura de PTFE

- Empaquetadura de PTFE Grafitado

- Empaquetadura de PTFE Puro con Las Esquinas Reforzadas con Fibras de Aramida

- Empaquetadura que Combina PTFE con Grafito y Esquinas de Aramida

- Empaquetadura de Fibra de Aramida

- Empaquetadura de Grafito Flexible

- Empaquetadura de Fibra Carbonizada

- Empaquetadura de Fibra Acrílica con PTFE

- Empaquetadura de Fibra Fenólica con PTFE

- Empaquetadura de Fibra Ramie

- Plancha de Asbestos Goma

- Plancha Comprimidas

- Plancha de Goma

- Plancha de Grafito

- Información

- Aplicaciones

- Contáctenos