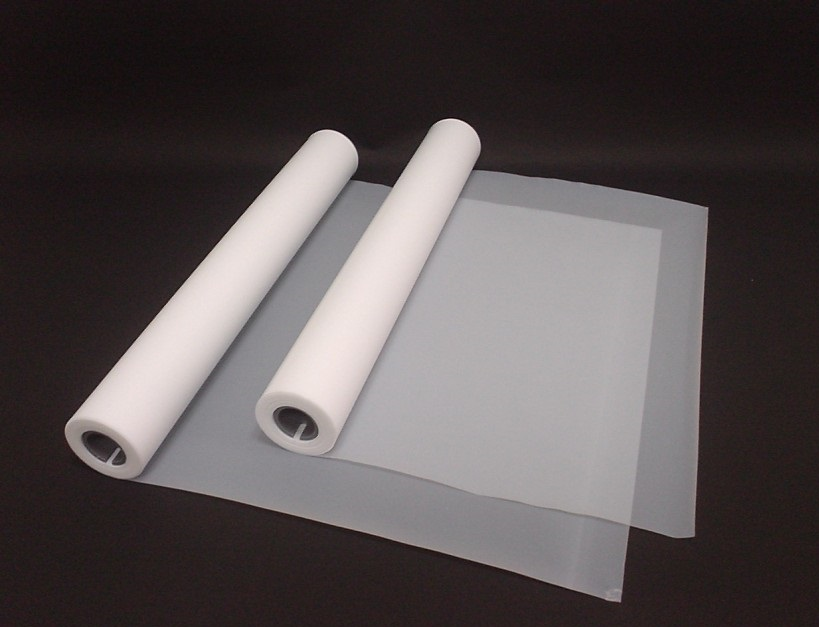

Skived PTFE (Polytetrafluoroethylene) sheet is a high-performance material produced by slicing thin layers from a solid PTFE block or billet through a process called skiving. This manufacturing method results in smooth, uniform sheets with excellent dimensional stability and consistent thickness.

One of the primary benefits of skived PTFE sheets is their outstanding chemical resistance. They are virtually inert to all chemicals, acids, solvents, and bases, making them ideal for use in harsh chemical environments such as laboratories, chemical processing plants, and semiconductor manufacturing. Additionally, skived PTFE sheets can operate across a wide temperature range from -200°C to +260°C, maintaining their properties under extreme heat and cold conditions.

Skived PTFE sheets also offer excellent electrical insulation, low friction, and non-stick characteristics. These properties make them suitable for applications such as gasket fabrication, electrical insulation barriers, lining of tanks and pipes, sliding bearings, and non-stick surface coatings.

The sheets are available in various thicknesses and can be easily cut, machined, or thermoformed to meet specific design and application requirements. Their high purity and smooth surface make them suitable for industries that demand contamination-free environments, such as food processing, pharmaceuticals, and electronics.

Overall, skived PTFE sheets provide a versatile, durable, and high-performance solution for a wide range of industrial, mechanical, and electrical applications where chemical resistance, thermal stability, and low friction are essential.