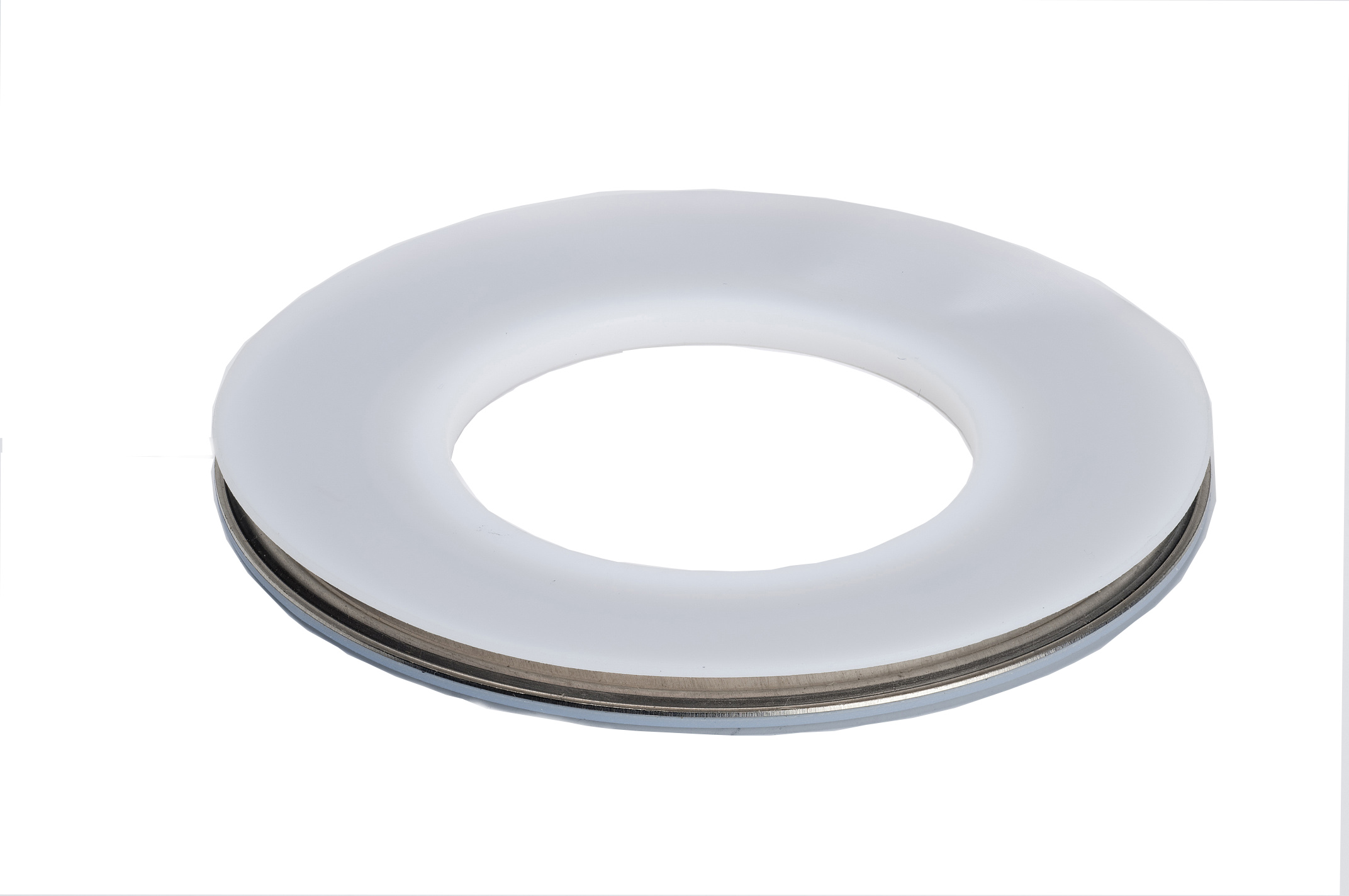

PTFE envelope gasket is a composite sealing product designed to combine the excellent chemical resistance of PTFE (Polytetrafluoroethylene) with the mechanical strength and flexibility of an insert material such as rubber, asbestos-free fiber, or metal. It features an outer layer—or "envelope"—made entirely of PTFE, which comes into direct contact with the process media, while the inner core provides structural support and enhanced sealing performance.

The primary advantage of PTFE envelope gaskets is their outstanding resistance to aggressive chemicals, acids, bases, solvents, and gases. Since PTFE is chemically inert and non-reactive, these gaskets are ideal for applications in the chemical, pharmaceutical, food processing, and petrochemical industries where corrosion and contamination must be avoided.

At the same time, the inner insert material allows customization based on specific sealing requirements. For example, an elastomer insert can offer excellent flexibility and resilience, while a metallic insert can provide superior pressure and temperature handling. This makes PTFE envelope gaskets suitable for a wide range of sealing applications, including glass-lined equipment, enamel reactors, and other sensitive or high-purity systems.

In addition to their chemical and thermal resistance (typically up to +260°C), PTFE envelope gaskets also offer good anti-stick properties, low friction, and minimal risk of product contamination. They are easy to install and remove, which simplifies maintenance procedures.

Overall, PTFE envelope gaskets provide a highly effective and versatile sealing solution, combining the best properties of PTFE with the strength and adaptability of various core materials to meet demanding industrial sealing challenges.