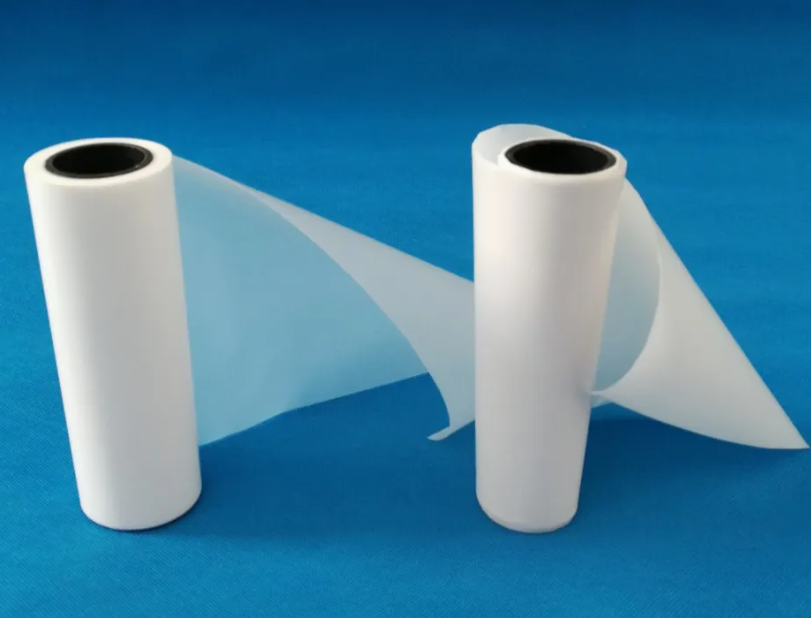

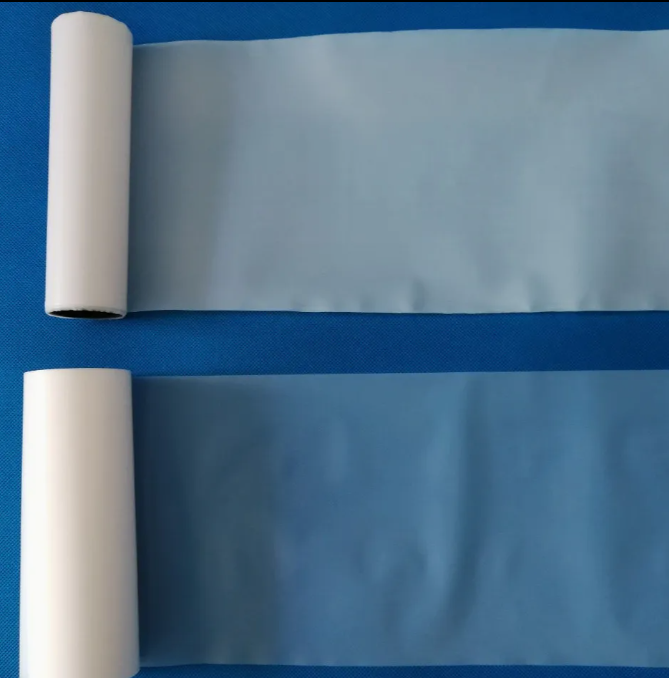

PTFE (Polytetrafluoroethylene) film is a high-performance material produced from pure PTFE resin through processes like extrusion, calendaring, or stretching. This results in a thin, flexible film with a smooth surface and a set of remarkable properties that make it indispensable in numerous industrial and commercial applications.

One of the key advantages of PTFE film is its exceptional chemical resistance. It is inert to nearly all chemicals, including strong acids, alkalis, solvents, and oxidizing agents. This makes it perfect for use in chemical processing facilities, where it can line tanks, cover equipment, or serve as a protective barrier against corrosive substances. Additionally, its chemical stability ensures long-term performance even in harsh chemical environments.

PTFE film can withstand an extremely wide temperature range, typically from -200°C to +260°C, without losing its physical or chemical properties. This temperature resistance allows it to function reliably in both cryogenic applications, such as in the aerospace industry for insulating components, and high-temperature settings, like in industrial ovens or engine compartments.

The material exhibits excellent electrical insulation properties. PTFE film has a high dielectric strength and low dielectric constant, making it an ideal insulating material in the electronics industry. It is widely used in capacitors, wire and cable insulation, and printed circuit boards, where it ensures reliable electrical performance and prevents short circuits.

Another advantage of PTFE film is its low friction coefficient and non-stick surface. This property makes it suitable for applications where reduced friction is essential, such as in bearings, gears, and sliding components. The non-stick surface also simplifies cleaning, which is crucial in the food processing and packaging industries, where PTFE film is used for conveyor belts and packaging materials to prevent products from sticking.

PTFE film is also highly resistant to weathering and UV radiation. It does not degrade when exposed to sunlight, rain, snow, or other environmental factors, making it suitable for outdoor applications. It can be used in architectural membranes, outdoor electrical enclosures, and protective covers, providing long-term durability in outdoor settings.

Moreover, PTFE film is non-toxic and inert, which makes it safe for use in food contact, medical, and pharmaceutical applications. It meets strict regulatory standards for purity, ensuring that it does not contaminate food products, medical devices, or pharmaceutical formulations.

Overall, PTFE film offers a combination of chemical resistance, temperature tolerance, electrical insulation, low friction, and durability, making it a versatile and reliable material for a wide range of applications across various industries.