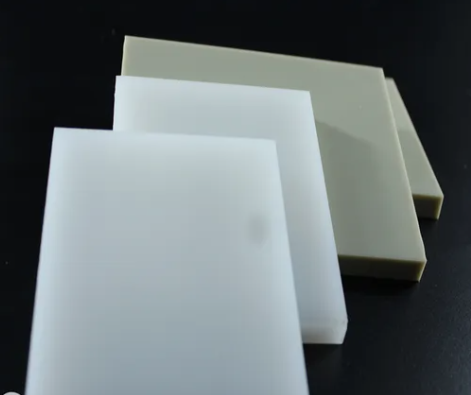

It is a plastic sheet made of polypropylene as the main raw material through extrusion molding and other processes. Its material has the characteristics of low density (about 0.90-0.91g/cm³), light texture, and good chemical stability, which makes it play an important role in many fields.

In terms of performance, PP sheet performs well. It has excellent chemical corrosion resistance. In addition to strong oxidizing acids such as concentrated nitric acid and fuming sulfuric acid, it has good resistance to most acids, alkalis, salts and organic solvents. This feature makes it very popular in the field of chemical corrosion protection. In addition, PP board also has a certain temperature resistance. It can be used for a long time in the temperature range of -20℃ to 100℃, and can adapt to temperature changes in different environments. Its mechanical properties are also considerable, with high impact resistance and tensile strength. At the same time, the surface is smooth, easy to process and weld, and can be cut, bent, bonded and other operations according to actual needs.

PP sheet has a wide range of uses. In the chemical industry, it is often used to make anti-corrosion equipment such as storage tanks, pipelines, valves, etc., effectively ensuring the safety of chemical production. In the food industry, PP sheet can be used to make food turnover boxes, linings of food processing equipment, etc. because it is non-toxic and tasteless and meets food hygiene standards. In the construction field, PP sheet can be used as decorative materials, sound insulation sheets, and the base of waterproof membranes. In addition, in the electronics, medicine and other industries, PP sheet is also used to make various parts and packaging materials due to its excellent performance.

In summary, PP sheet has an irreplaceable position in many industries due to its unique material and excellent performance. With the continuous development of technology, its application field will be further expanded.