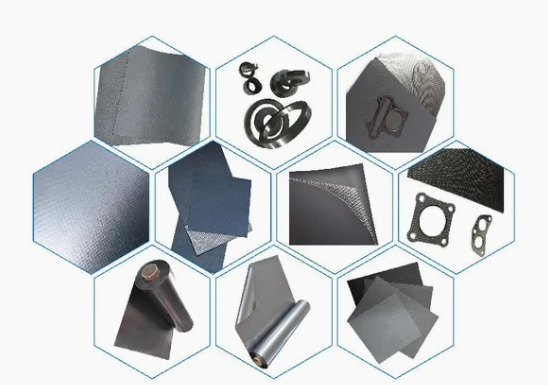

Graphite sheet, a sheet material made primarily from natural or synthetic graphite, holds a significant position in the industrial sector due to its unique physical and chemical properties. While retaining the inherently excellent properties of graphite, it also accommodates diverse applications through processing and shaping, making it an indispensable key material in modern industrial production.

Graphite sheet offers exceptional performance characteristics.

First, it is extremely heat-resistant, remaining stable at temperatures up to 3000°C. It does not melt even in high-temperature environments, sublimating only at 3652°C. This characteristic makes it exceptionally suitable for high-temperature industrial applications.

Second, it possesses excellent electrical and thermal conductivity, comparable to that of some metals. Its excellent thermal conductivity allows for rapid heat transfer, meeting the thermal management requirements of a wide range of equipment.

Graphite sheet also exhibits excellent chemical stability. At room temperature, it is resistant to reactions with chemicals such as acids and alkalis, and exhibits only limited sensitivity to strong oxidizing substances. This ensures a long service life in corrosive environments.

Furthermore, its excellent lubricity and low coefficient of friction reduce wear and tear during equipment operation.

Graphite sheets are used across a wide range of industries.

In the metallurgical industry, they are often used as electrode materials for electrolytic cells and linings for high-temperature furnaces, leveraging their high-temperature resistance and electrical conductivity to aid the metallurgical process.

In the chemical industry, graphite sheets are ideal for corrosion-resistant pipes and reactor linings, effectively resisting chemical corrosion.

In the electronics industry, they are used as heat dissipation materials in chips, electronic components, and other devices, helping to quickly dissipate heat and ensure stable operation of electronic devices.

In the new energy sector, graphite sheets are also used in key components such as bipolar plates in fuel cells, driving the development of new energy technologies with their electrical conductivity and chemical stability.

With the continuous innovation of industrial technology, the application scope of graphite sheets continues to expand. Their excellent performance will provide strong support for the development of more industries, showing a broad market prospect.