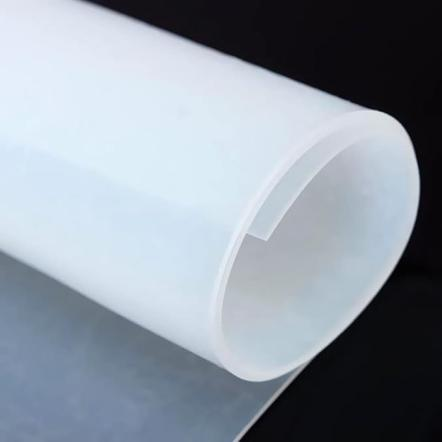

Silicone sheet is a high-performance elastomeric material manufactured from virgin silicone rubber that is calendered and vulcanized into uniform, flexible sheets. This unique molecular structure (Si–O backbone) gives silicone sheets exceptional thermal stability, electrical insulation and chemical inertness, making them the material of choice for the most demanding sealing, cushioning and insulating applications across aerospace, automotive, medical, food-processing and electronics industries.

One of the key advantages of silicone sheets is their outstanding temperature resistance. They maintain full flexibility and sealing properties from –60 °C to +230 °C continuous (up to +270 °C intermittent) without hardening, embrittling or melting—far beyond the reach of EPDM, neoprene or nitrile sheets. Additional post-cured grades extend continuous service to +300 °C, ideal for turbocharger gaskets, oven door seals and PCB wave-solder pallets.

The inorganic backbone also provides excellent dielectric strength (up to 20 kV/mm) and volume resistivity (>10¹⁴ Ω·cm), so silicone sheets serve as reliable electrical insulators in high-voltage connector pads, keyboard membranes and solar-cell backing. Flame-retardant grades meet UL 94 V-0 and low-smoke EN 45545 requirements for rail and aviation interiors.

Silicone sheets exhibit superior elastic recovery and compression-set resistance (<10 % after 22 h @ 175 °C), ensuring a tight, long-life seal with minimal bolt torque on uneven, warped or thermally cycling flanges. This reduces maintenance downtime in pumps, heat exchangers, sterilizers and chemical reactors. Specialty platinum-cured grades offer <1 % extractables, meeting USP Class VI and FDA 21 CFR 177.2600 for pharmaceutical and beverage tubing gaskets.

Another advantage is environmental compatibility. Silicone sheets are inherently inert to UV, ozone, moisture and weathering, showing no cracking after 5 000 h Q-UV-B exposure. They resist diluted acids, bases, polar solvents and brake fluids, and remain flexible in Arctic oilfields or tropical rooftops. Low-friction, non-stick surfaces release easily from press platens and prevent gaskets from bonding to metal flanges over time.

Overall, silicone sheets deliver unmatched thermal endurance, electrical safety and long-term resilience, providing a reliable, high-purity solution for engineers facing extreme-temperature sealing, cushioning and insulation challenges.