The term cast nylon refers to type 6 nylon polyamides that are produced through a highly controlled casting method. These polymers have a highly crystalline molecular structure. Initially, the raw material, known as caprolactam, goes through a controlled polymerization process, resulting in semi-finished forms of type 6 nylon.

One of the main advantages of cast nylon is its versatility. By incorporating additives such as oil, solid lubricants or thermal stabilizers, it is possible to adjust the typical characteristics of type 6 nylon according to the specific needs of different applications and industries.

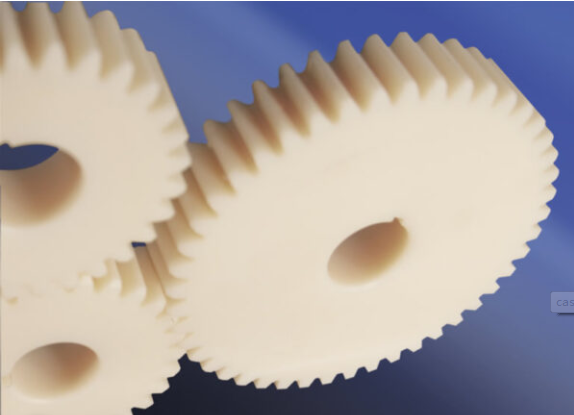

Compared to extruded nylon, cast nylon exhibits even greater crystallinity and improved machinability. These properties result in final products with optimized performance, making cast nylon an excellent choice for sectors that demand strength, durability and adaptability, such as the manufacture of technical parts, industrial components and applications that require strict tolerances.

In summary, cast nylon represents a group of type 6 nylon polymers manufactured through a controlled casting process. Its distinctive advantage lies in the possibility of adjusting its properties through additives, resulting in materials tailored for a wide range of industrial applications, while offering greater crystallinity and machinability compared to extruded nylon.