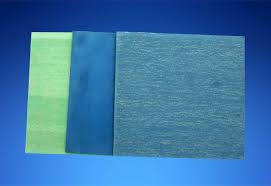

As a green and environmentally friendly sealing material, asbestos-free boards are gradually replacing traditional asbestos products and becoming the new favorite in the sealing industry. Recently, many domestic companies have made significant progress in the production, processing and application of asbestos-free boards, setting a new benchmark for promoting the green development of the industry.

1. Innovation and development of production and processing technology

In recent years, my country has made important breakthroughs in the production and processing of asbestos-free boards. Take Yantai Ishikawa Gasket Co., Ltd. as an example. The company's predecessor was the Yantai Asbestos Products General Factory established in 1950. In 2001, it merged with the asbestos technology and production line of Japan's Ishikawa Gasket Co., Ltd. and became the largest enterprise specializing in the production of sealing products in China. one. Yantai Ishikawa Company has not only successfully developed a variety of asbestos-free sealing sheets, but has also obtained a number of national invention patents and recognition from authoritative European testing agencies in other fields, and has exported them to Japan, South Korea, Australia and other countries and regions.

During the production process, wet copying and long netting are used, which not only improves production efficiency, but also significantly reduces dust-free production, effectively protecting the physical and mental health of employees. In addition, the raw materials of asbestos-free boards mainly include organic fibers, waste paper boxes, inorganic slag fibers and a large number of inorganic fillers, such as talc powder, kaolin, etc. These materials are not only environmentally friendly, but also greatly reduce the dependence on wood fibers and save energy.

2. Extensive expansion of application fields

Asbestos-free boards have been widely used in many fields such as construction, industry, and automobiles due to their excellent performance. In the construction field, asbestos-free fiber cement slabs are used for their good heat resistance and durability in wall panels, roofs and floors. In industrial and commercial buildings, asbestos-free panels are also favored for their excellent sealing and environmental friendliness.

In the automobile industry, asbestos-free sealing materials have become a key technology for automobile upgrading. Enterprises such as China Second Automobile Industry Corporation, Tianjin Automobile Industry Company, FAW, etc. have already used asbestos-free automobiles. In addition, with the continuous development of the international market, more and more Many Chinese car brands have also begun to use imports to meet increasingly stringent environmental protection requirements.

3. With the continuous improvement of global environmental protection requirements, the market prospects of asbestos-free boards are very broad.

According to statistics, the asbestos-free fiber cement slab market has shown steady growth over the past few years and is expected to continue this trend in the coming years. At the same time, as asbestos-free boards are used in more fields in China, with the adjustment of industrial structure and the continuous increase of environmental protection policies, asbestos-free products have become one of the key development upgrade products. Large enterprises such as Shanghai and Baoshan Iron and Steel Group have explicitly prohibited the use of asbestos-containing products, providing a broad market space for stone-free products.

As a new star in the environmental sealing industry, it is leading the new trend of the industry with its excellent performance and wide range of application fields. In the future, with the continuous advancement of technology and the continuous development of the market, asbestos-free boards will play an important role in more fields and make greater contributions to environmental protection and economic development.